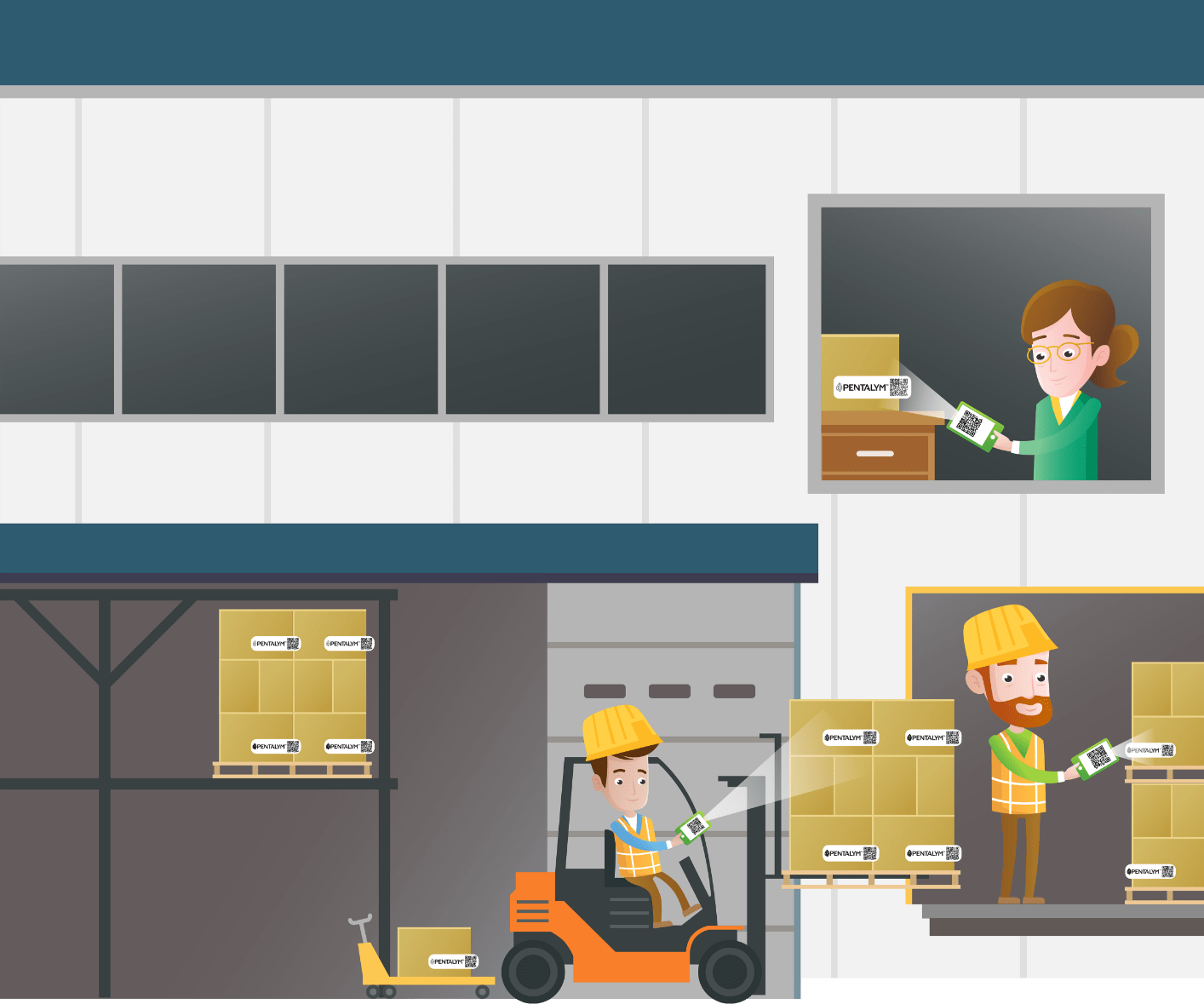

As a warehouse manager on receipt of a sales order, Pentalym enables you to see your products packed and loaded from warehouse storage locations right through to your end customers.

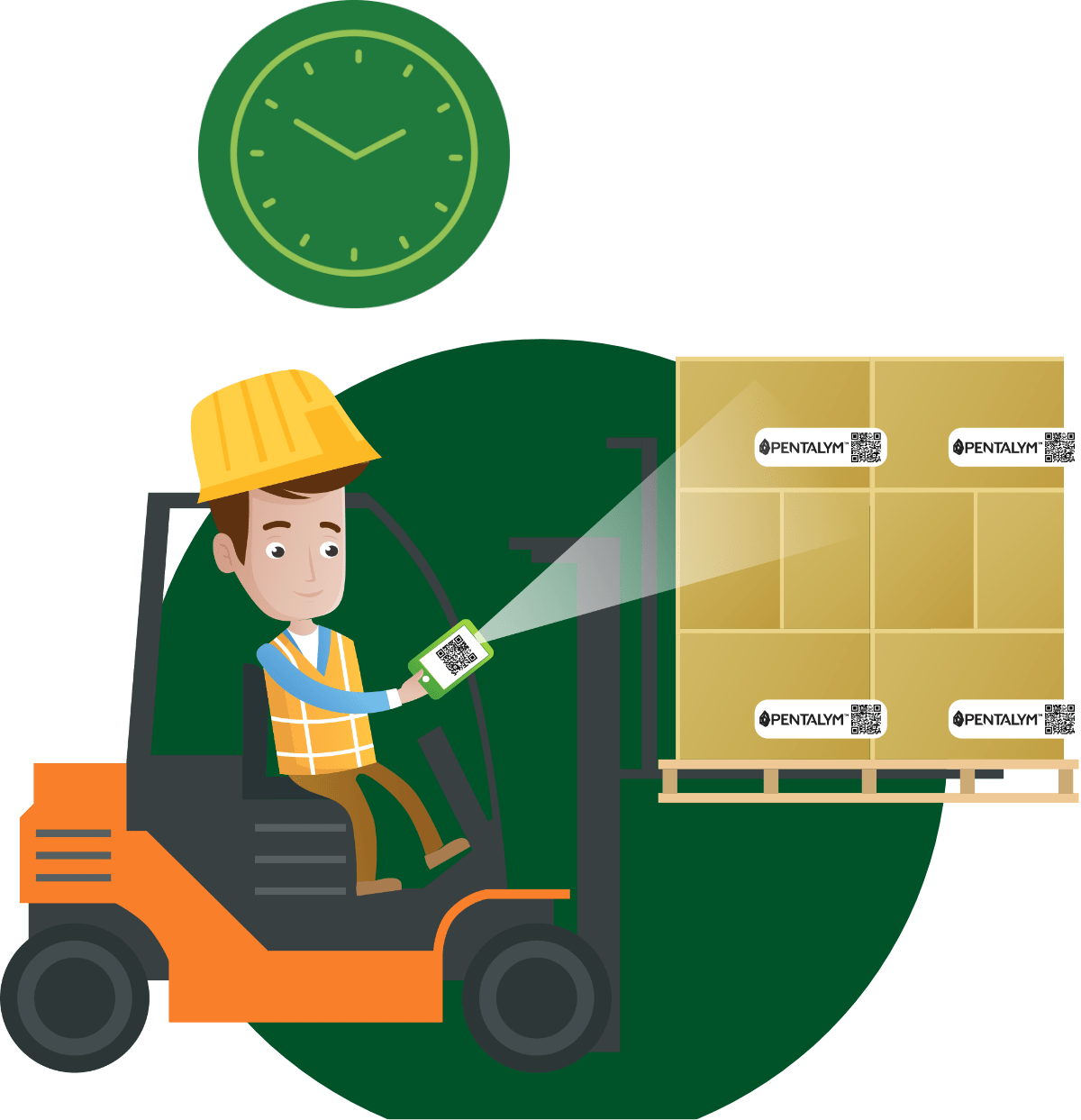

Utilising Pentalym in conjunction with your sales order enables you to identify and notify forklift drivers if the picked product does not match the product on the sales- order.

Customers have piece of mind receiving their order knowing the inventory was checked and digitally receipted prior to signing off. Every order can be uniquely managed to notify if there is a problem i.e. product damage, missing inventory etc.

Tagging products at source – if you do your own packaging, tagging at the point of packaging. The ability to pre-allocate/pre-Connect tags to a specific product + pallet combination enables streamline placement of tags onto your products.

Ability for dispatch driver to scan a product or delivery note and have the customer sign-off on a delivery using the QR code system. Enables customer to communicate in real time if there is a problem, acceptance or rejections of product, customer signature.

Example outbound flow:

- Customer places an order, Inventory tagged with a unique identifier (Item tagged at source either during production/ packaging process or on inventory receipt eliminating need for re-work) initiating live data tracking.

- Inventory palletised/packaged and moved to dispatch location, tag verifies inventory matches the customer order and whether or not product is been stored in the right location for dispatch (Improves product handling efficiency/availability)

- Warehouse staff pick product for loading, tag notifies when Inventory has left the dispatch area (Increases accuracy and reduces staff labour time spent taking inventories)

- Dispatch driver scans receipts of inventory, tag notifies inventory matches customer order (eliminates paperwork, reduces human error, enables identification of product issues before reaching end customer)

- Order departs tracking information sent to both supplier and end customer (Real time visibility enables quick action for process improvements saving significant cost)

- The storage of pallets – each pallet/product should be stored at a specific location to optimise operations. System will provide notification if the product is stored in the wrong location.

Pentalym’s solution is inexpensive , scalable and backed by secure cloud based software available anytime anywhere.